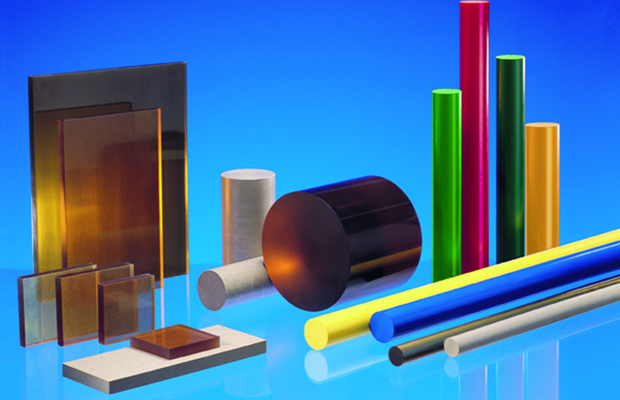

High Performance Plastics Exhibit Superior Mechanical Properties, Outstanding Thermal Stability and Superior Chemical Resistance

|

| High Performance Plastics |

High Performance Plastics meet more stringent performance requirements than standard plastics. These materials are more expensive and typically used in smaller quantities, they are more durable also. They can be used for a range of applications. This makes them the best choice for many applications. High-performance plastics are also more environmentally friendly and they exhibit high performance standards.

High-performance plastics can maintain their properties over a wide temperature range. They typically exhibit a permanent operating temperature of more than 302 degrees Fahrenheit (158 degrees Celsius). They can also offer weight savings and excellent chemical resistance. These materials can also be reinforced with special reinforcing materials or additives. For example, they can be reinforced with metal fibers or carbon black.

According

to Coherent Market Insights the High

Performance Plastics Market Global Industry Insights, Trends, Outlook,

and Opportunity Analysis, 2022-2028.

High-performance plastics are widely used in many industries for their outstanding chemical resistance. Some of the most common examples of these materials include PPS and PAI, which are resistant to a broad range of chemicals. These materials are also very durable and often replace metal, wood, and glass. As a result, they offer outstanding performance and quality.

Another advantage of high performance plastics is that they are easily molded to produce complex geometries and thin-wall components. This gives engineers great flexibility in design. The material also has excellent thermal and chemical properties and is safe to use. It is also biocompatible, which makes it an excellent choice for medical device applications. These products are used in industries such as aerospace, deep-hole drilling, food processing, and glass manufacturing. While these materials can be expensive, they offer a good balance between performance and cost.

Engineers working in this field are often challenged to process these materials as they have a wide range of physical, thermal, and chemical properties. Understanding the properties of each material is essential for success. To create a high-performance part with optimal performance, engineers must be familiar with the material and understand how it reacts to different temperature and pressure conditions. They must also master the proper handling and processing techniques.

In July 2020, Valtrex, which is a leader of high-performance polyaryletherketone and polyetheretherketone polymer solutions launched the VICTREX AM™ 200 filament. This has been developed for optimizing additive manufacturing.

Comments

Post a Comment