Laser Processing Is a Versatile Technique That Can be Used for a Wide Range of Applications

|

| Laser Processing |

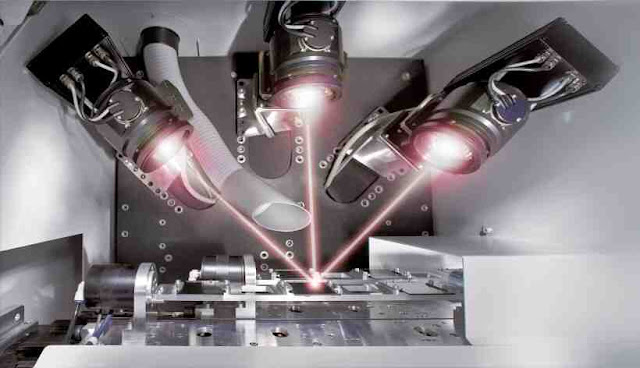

Laser Processing is used for metal and non-metal processing, surface modification, micro/nanofabrication, and structured fabrication. Its benefits include fast production, low cost, and repeatability. Several different factors can affect the efficiency of the process, including laser energy, laser intensity, and the geometry of the beam. The energy of the laser beam can be modified by changing the shape, depth, and direction of the beam, and it may also be altered by changes in the workpiece. Changes in the geometry of the workpiece can be beneficial in some applications, but they can be detrimental in others.

Often, a beam guidance module, such as a robotic arm, is used to direct the laser beam along the workpiece. Other optical components, such as fiber optic cables or beam benders, can be used in the same way. For some processes, the absorption of the laser beam may be enhanced by injecting process gas. In these processes, the gas can couple with the energy of the laser, and the vapor channel can serve as a waveguide, a waveguide for keyhole welding, or as a source of radiation for a variety of applications.

Laser Processing Market was valued at US$ 19,162.9 Mn in 2021 and is expected to reach US$ 46,642.6Mn by 2030, growing at a CAGR of 10.0% between 2022 and 2030.

Another important factor in the performance of a laser is the shape of the transverse beam. A transverse beam's shape can have a great impact on the distribution of the laser's radiation and the efficiency of the process. To control the beam, a laser processing head can be moved over the workpiece or mounted on a movable robot arm. Depending on the application, the transverse beam shape can be influenced by the laser's wavelength, the diameter of the laser's focal spot, and the pulse shape of the laser.

The Non-Destructive Testing Market is a rapidly growing industry, as it allows for the inspection of materials and components without causing damage. This type of testing is used in a variety of industries, including aerospace, automotive, oil and gas, and construction. There are several different methods used in non-destructive testing, such as X-ray, ultrasonic, and magnetic particle inspection.

Aside from the optics, the other critical component of a laser system is the beam delivery system. An articulated arm delivery system ensures that the diffraction-limited beam quality of the beam is maintained. However, the mechanics of such systems are delicate. They require delicate handling of mirrors and other mirrors, and contamination can be a problem.

Comments

Post a Comment